NGIMES MES for Industry 4.0 | MES with IIOT | Integrated MES | Next Generation MES

Faster MES implementations and Instant value realization with NGIMES

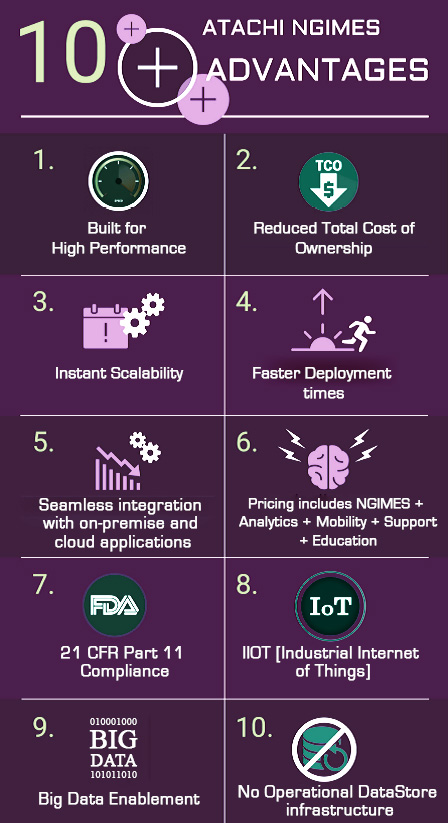

In today’s fast-moving global business environment, simply relying on some key performance indicators (KPIs) to make crucial business decisions is not going to cut it. You need a modern, MES for Industry 4.0 system that can keep pace with shifting customer preferences and strict quality demands. With the Industrial Internet of Things (IIoT) revolutionizing manufacturing by leveraging intelligent, connected devices, there are even more opportunities to fine-tune operations with better data and tighter process integration.

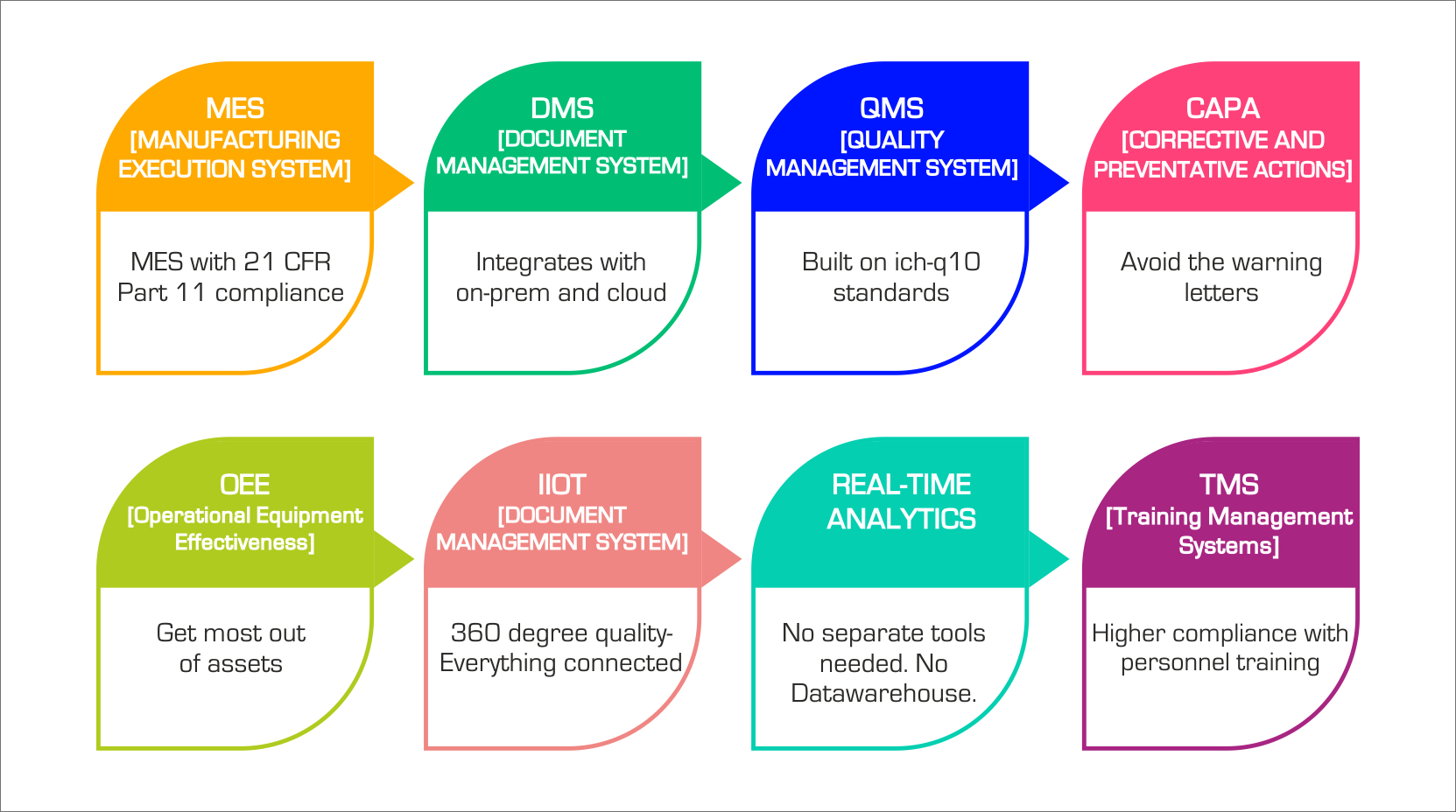

The Next Generation Integrated MES (NGIMES) from Atachi Systems in the cloud powered with SAP HANA platform for Manufacturing, Pharmaceutical, Automotive & Electronics companies. A cloud based MES - NGIMES is quick to deploy and minimizes deployment, maintenance and licenses costs so you can maximize profits.